Technical Data

2015-04-21

1,Electrical resistance(Unit:μΩ.m):

| Grade Electrical Resistance |

UHP |

SHP |

HP |

HD |

RP |

| Pole |

Max(≤) |

5.5 |

5.6 |

6.5 |

6.8 |

8.5 |

| Min(≈) |

5.2 |

5.3 |

6.2 |

6.5 |

8.2 |

| Nipple |

Max(≤) |

3.8 |

4.0 |

4.8 |

4.8 |

5.8 |

| Min(≈) |

3.5 |

3.6 |

4.5 |

4.5 |

5.5 |

Measuring Method:Field strength measuring principle;

The electrode tip(AWG graphitization)should be 100% inspected, the upper limit of resistivity is 9.0μΩ.m;

The resistivity difference between the electrode and nipple is more than or equal to 1.0μΩ.m, the best is 20%.

2,Bulk density(Unit g/cm3):

| Variety Density |

UHP |

SHP |

HP |

HD |

RP |

| Lowest |

Highest |

Lowest |

Highest |

Lowest |

Highest |

Lowest |

Highest |

Lowest |

Highest |

| Electrode body |

1.68 |

1.73 |

1.66 |

1.73 |

1.65 |

1.73 |

1.65 |

1.73 |

1.58 |

1.65 |

| Mean |

1.7 |

1.69 |

1.68 |

1.68 |

1.6 |

The volume density of the nipple in the minimum control range is more than or equal to 1.70 g/cm3 (when volume density of the electrode pole less than or equal to 1.59).

Electrode pole and nipple’s volume density matching differential control range:

| volume density range of the electrode body(g/cm3) |

volume density difference between the electrode body and nipple (g/cm3) |

| ≤1.62 |

≥0.10 |

| 1.62~1.65 |

≥0.09 |

| 1.65 ~1.68 |

≥0.08 |

| 1.65~1.70 |

≥0.07 |

| 1.70~1.74 |

≥0.06 |

| ≥1.70 |

≥0.05 |

| ≥0.08 g/cm3。 In the specification of the electrode diameter more than or equal to 550mm, Volume density difference should be controlled more than or equal to 0.08 g/cm3 |

3,Flexural Strength

| Variety Strength |

UHP |

SHP |

HP |

HD |

RP |

| the minimum of the electrode pole |

13.0 |

12.0 |

11.0 |

11.0 |

9.0 |

| the minimum of the nipple |

24.0 |

23.0 |

22.0 |

22.0 |

18.0 |

4,Thermal Expansion(the unit 100 to 600 ° C,10-6 / ° C) :

| Variety Thermal Expansion |

UHP |

SHP |

HP |

HD |

RP |

| the minimum of the electrode pole |

1.2 |

1.5 |

1.8 |

2.2 |

2.5 |

| the minimum of the nipple |

1.1 |

1.3 |

1.5 |

1.5 |

2.2 |

5,Ash(Unit%):

| Variety Ash |

UHP |

SHP |

HP |

HD |

RP |

| ≯Electrode body and the nipple are ≯ |

0.3 |

0.3 |

0.3 |

0.3 |

0.3 |

Share With:

Pre:Back To List

Next:The size of electrode and nipple

-

.jpg)

- Carbon electrode

- Carbon electrode is energy saving, environmentally friendly product, used in the calcium carbide, ferroalloy submerged arc furnace, also can greatly reduce the power consumption, and pollution.

-

- Calcined petroleum coke

- Calcined petroleum coke is mainly used for the production of graphite electrodes, carbon paste products, diamond sand, the food grade phosphate industry, metallurgical industry, manufacturing calcium carbide.

-

- Graphitization of petroleum coke

- Petroleum coke is residue in the refining process.

-

- Graphite scrap

- Graphite scrap mainly comes from the debris generated graphite electrode machining and graphitizing process.

-

- Graphite powder

- Graphite powder mainly comes from the debris generated graphite.

-

- Calcined anthracite

- Hongxin carbon has three series products: graphite quality carburant, carbonaceous carburant, coal quality carburant.

-

.jpg)

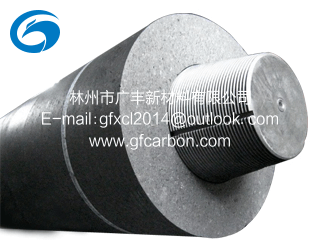

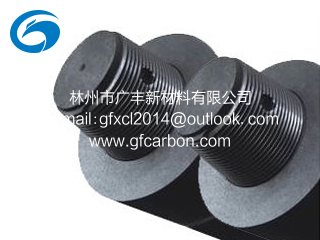

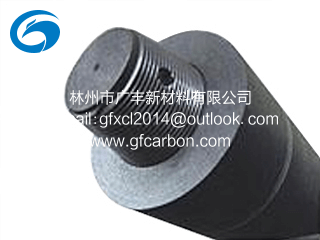

- Nipple

- Graphite electrodes use petroleum coke, needle coke as raw material, coal tar pitch

as binder, through mixing, extruding, baking, graphitizing, and machined to the shape.

-

- UHP graphite electrode

- Ultra high power graphite electrode (UHP/SHP)is a high-end product of artificial graphite.

-

- HP graphite electrode

- High power graphite electrodes (HD / HP) is made of high quality traditional petroleum coke.

-

- RP graphite electrode

- Regular power graphite electrodes (RP) is made of the traditional low-sulfur petroleum coke as the base material.

-

- Rounded graphite

- Product applications: mainly used in solar thermal field, smelting, mold, foundry and semiconductor industry.

-

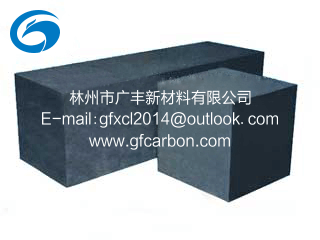

- Square graphite

- Product applications: mainly used in smelting, mold, foundry and semiconductor industry.

-

- Cold ramming paste

- Cold ramming paste is a carbon material used for masonry, widely used in aluminum reduction cell, blast furnace, smelting furnace

-

- Electrode paste

- Electrode paste was supplied to ferroalloys furnace, carbide furnace equipment as conductive materials.

-

- Partial graphite carbon block for blast furnace

- Using high temperature electric semi graphitized anthracite with low ash and artificial graphite as the main raw material.

-

- Carbon block for blast furnace

- Electrode paste was supplied to ferroalloys furnace, carbide furnace equipment as conductive materials.